What is Cat et software used for?

CAT Electronic Technician (ET) Cat® ET is diagnostic software that helps technicians diagnose existing and potential problems with their electronically controlled Caterpillar engines and machines. The software accesses information when connected to the Electronic Control Module (ECM).

CAT Caterpillar ET Diagnostic Tool from Caterpillar provide the capability to access Electronic Control Modules (ECMs) from a personal computer. Many job-critical tasks can be performed with an electronic service tool. The user can display the status of a group of parameters (temperatures, pressures, etc.) simultaneously, view active and clear logged diagnostics, display the current configuration of an ECM and much more. The service tool works with a communication adapter to allow connection to an ECM. A graphical interface makes this software quick to learn and easy to use. A separate pull-down menu for each function enhances the “ease of use.” The version and identification of the ECM is automatically retrieved and is displayed on a summary screen when the program is started. Diagnostic tests and calibrations can also be performed.

CAT Caterpillar ET Diagnostic Tool enable service technicians to reprogram ECMs, reconfigure control system parameters, fine tune performance or diagnose the root cause of a failure the first time. These powerful tools allow service personnel to display and analyze vital performance and health information from any system quickly and accurately. The service tool communicates with any system using ATA (J1708), J1939 or the Caterpillar proprietary data link networks. The service tools provide information and features needed to help a technician diagnose problems and perform repairs and to customize and personalize the operation of a product. By allowing customers to design flexibility and configurability into a product, Caterpillar service tools stretch beyond the capabilities of preprogrammed ECMs or onboard display systems.

With the CAT Diagnostic Tool, you can:

View active and logged diagnostics

View events where irregularities occurred and were logged by the ECM

View the status of a group of parameters (temperatures, pressures, etc.) simultaneously

Record and log performance data

Graph a group of status parameters

View the current configuration of an ECM

Change ECM configurations

Perform diagnostic tests

Perform calibrations

Print reports and diagnostic results

For some machine and engine products, additional functionality has been included with the service tool program

PC, Communication Hardware, and Cable Requirements

To run the service tool, the next PC, communication hardware, and cable requirements must be met. NOTE: The minimum PC Configurations should not be used as a standard when buying new personal computers for service tool purposes. If the existing equipment meets these minimum requirements, it will run the service tool.

PC Requirements

Recommended Configurations

PC containing a 2.0 GHz dual-core processor

3GB RAM

3GB of the available hard disk drive

DVD-ROM drive (optionally)

15.4-inch XGA Screen (1280×1024 compatible)

Microsoft Windows™ 7 Professional or Windows 8 Professional, Windows 10 Professional (Not tested with Home Edition) (Note: Windows 8 RT is not supported)

RS232 port with 16550AF UART or compatible (for use with Comm Adapter II)

USB 1.1 or 2.0 port (for use with Comm Adapter 3)

Ethernet RJ45 connector

Built-in pointing device or mouse

For security purposes, Microsoft Internet Explorer version 11 or newer or Microsoft Edge is recommended.

Note: The most recent version of Microsoft Internet Explorer may not be validated to work with the service tool.

Wi-Fi (for the Wireless Comm Adapter 3)

The list of supported CAT machines and engines can be found below:

Engines:

Electric Power

Electric Power Generation

Industrial

Marine Power Systems

Oil and Gas

Machines:

Articulated Trucks

Asphalt Pavers

Backhoe Loaders

Cold Planers

Compactors

Dozers

Drills

Excavators

Feller Bunchers

Forest Machines

Forwarders

Harvesters

Hydraulic Mining Shovels

Knuckleboom Loaders

Material Handlers

Motor Graders

Off-Highway Trucks

Pipelayers

Road Reclaimers

Site Prep Tractors

Skid Steer and Compact Track Loaders

Skidders

Telehandlers

Track Loaders

Underground – Hard Rock

Underground – Longwall

Underground – Room and Pillar

Utility Vehicles

Wheel Dozers

Wheel Excavators

Wheel Loaders

Wheel Tractor-Scrapers

Packing list:

1.Real CAT et3 Comm Adapter III (it’s real cat et 3,not adapter 2,please check Communication port)

2.J1939/J1708 Cable (from device to your truck)

3.ET software DVD (for windows XP or windows7 32bit system)

4.14PIN Cable(for new truck)

5. 6pin cable ( For old trucks )

Caterpillar ET 3 Main Features :

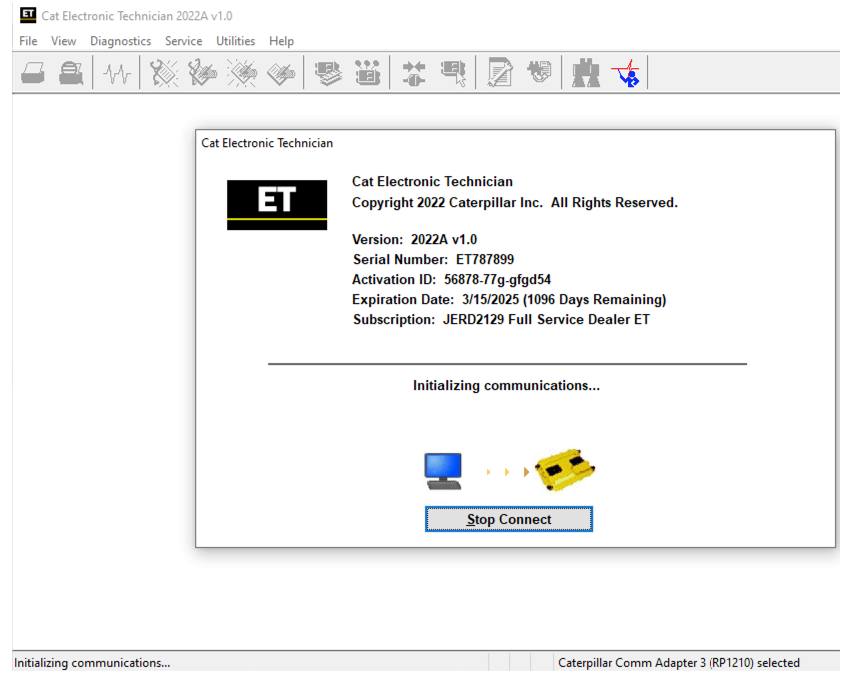

1. Latest Version:2022A/2021B/2019C(optional)

2. Supported Operating System: Windows 7 32 bit, Wnidows 7 64 bit, Windows 8/8.1 32 bit, Windows 8/8.1 64 bit, Windows 10 32 bit, Windows 10 64 bit

3. We will activate it after installing 2022A/2021B/2019C version software.(After the installation , please contact us help you active the software by remote)

4. Supported Language: Chinese(Simplified), Danish, German(Germany), French(France), Portuguese (Portugal), Japanese, Spanish (tradition), Italian(Italy), English(America)

5. Support caterpillar diagnostic till 2022

Caterpillar ET 2022A is a good replacement for the CAT ET 2019C, 2021B Electronic Technician Diagnostic Software. 2022A Caterpillar Electronic Technician software With CAT ET 3 Cat caterpillar adapter 3 support caterpillar diagnostic till 2021.

Contact us if you need CAT Caterpillar ET Diagnostic Tool, our website sale@cnautotool.com