Communications Adapter 3 Description:

CAT Communications Adapter 3 is the latest generation of the Communication Adapter group, and replaces the Comm Adapter II. This is the only recommended communication device for ET 3,and the only data link device that will allow you to properly communicate with a CAT engine on dual datalinks. This function is needed for some ET (Electronic Technician) functions.

CAT Caterpillar ET Diagnostic Tool from Caterpillar provide the capability to access Electronic Control Modules (ECMs) from a personal computer. Many job-critical tasks can be performed with an electronic service tool. The user can display the status of a group of parameters (temperatures, pressures, etc.) simultaneously, view active and clear logged diagnostics, display the current configuration of an ECM and much more. The service tool works with a communication adapter to allow connection to an ECM. A graphical interface makes this software quick to learn and easy to use. A separate pull-down menu for each function enhances the “ease of use.” The version and identification of the ECM is automatically retrieved and is displayed on a summary screen when the program is started. Diagnostic tests and calibrations can also be performed.

CAT Caterpillar ET Diagnostic Tool enable service technicians to reprogram ECMs, reconfigure control system parameters, fine tune performance or diagnose the root cause of a failure the first time. These powerful tools allow service personnel to display and analyze vital performance and health information from any system quickly and accurately. The service tool communicates with any system using ATA (J1708), J1939 or the Caterpillar proprietary data link networks. The service tools provide information and features needed to help a technician diagnose problems and perform repairs and to customize and personalize the operation of a product. By allowing customers to design flexibility and configurability into a product, Caterpillar service tools stretch beyond the capabilities of preprogrammed ECMs or onboard display systems.

CnAutotool.com Communications Adapter III Feature:

1. WiCaterpillar Communication Adapter3

2.Allows communication between service tools and engine controls using various data links such as J1939/11, DeviceNet

(future release), CT DataLink, and J1708 (ATA) vehicle networks;

3.Flash program allows adapter firmware upgrades as additional features become available;

4.Uses J1939/11, high-speed data link (part of ADEM III controls), substantially reducing flash times;

5.Automatically selects J1939/11 when flashing the engine (reduces the flash time approximately 80%, from 14 minutes to 3 minutes).

Main Functions

1.ECM Summary screen lists every control module on equipment

2.Being tested and gives information on these modules.

3.Fast hookup and real time display of systems status. Displays ,readings such as rpm, boost, pressures, temperatures, etc. for Easy troubleshooting.

4.Identifies faulty sensors, harness connectors, and system parameters which are out of specification. Allows customers

5.To help dealer identify problems without visiting machine.

6.Identifies intermittent sensors and wiring problems during Machine operation and keeps a record of each one. Showswhen problem occurred and how often it happened.

7.Added information to allow customer to assist dealer in diagnosing and repairing problems. (Troubeshooting Help is not built in with in the program, you will still need go back to books in order to follow a repair description and steps in each Fault Code display within the program).English and metric units of measure integrated help file to easy learn the “How To” around the software.

Note:

1.Functionalities Shows all operating conditions that cause high repair costs such as:

Over speeds, high temperatures, fuel consumption, transmission shift counts. This can provide awareness to change operator.

2. “ET Trainer” is now included in ET Program. It allows Users to train and practice using ET without a Communications adapter or Electronic Control Module (ECM).This is a free feature of ET

Customised Service Tool Options

Customized service tool name

Customized graphics for the splash screen and icons

Customized installation

Aftermarket differentiation, i.e., the tool for one customer does not work on the product of another customer.

Licensing options for customer management

Flash programming of the ECM(s)

Training demonstration allows familiarity with the tool’s primary functions without connecting to ECM(s)

Perform customized diagnostic tests to identify harness problems, cylinder or component failures (Automatic Cylinder Cutout with cylinder to cylinder fueling comparison)

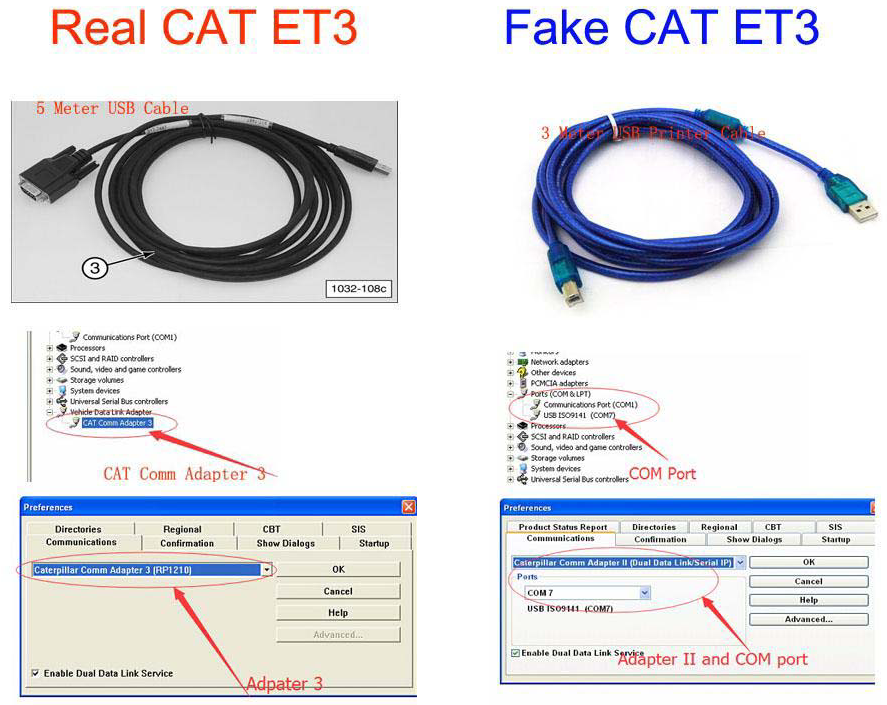

Original Factory Caterpillar ET3 Adapter III Compare With OEM Caterpillar ET Diagnostic Adpater III

1. Original Factory CAT ET can use once pluged, no need install the USB drive, the software can automatic realize it for ET3 Adapter, and the machine can automatic weld the high quality Circuit board, quality will be more reliable.

2. The OEM Caterpillar ET Diagnostic Adapter III need use USB Drive to install, and need choose the COM Port, and in the software ET also need choose ET2 then can be used.

The Details as follows: