As a excellent Professional Diagnostic Tools products, CAT Caterpillar ET Diagnostic Adapter has a powerful function.it not only can Display “Logged Event Codes” to show engine over speeds,High temperatures, fuel consumption but also can view ECM’s current configuration and change user settings,perform diagnostic tests and calibrations, and calibrate.Electro-mechanical and electro-hydraulic components .

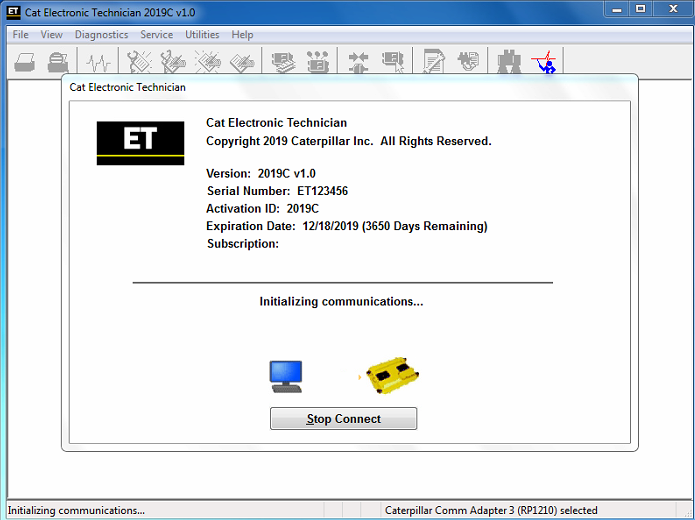

Caterpillar ET 2019C (replaces CAT ET 2018b, 2019A,2019B) Electronic Technician Diagnostic Software :

Brand: Caterpillar

Region: WorldWide

Support Multi-language :English, Chinese, Danish, French, German, Italian, Japanese, Portuguese, Russian, Spanish

Publication date: 10.2019 year

Support All cars of CAT

This is the only recommended communication device for CAT, and the only datalink device that will allow you to properly communicate with a CAT engine on dual datalinks. Context sensitive help leads operator through every task Cat ET can perform. Data Logger and Data Log Viewer allows recording of ECM signals for delayed troubleshooting capability.Cat “ET Trainer” is now included in ET Program. It allows Users to train and practice using Cat ET without a Communications adapter or Electronic Control Module (ECM).This is a free feature of Cat ET.

It is the latest generation of the CAT Communication Adapter group, and replaces the Caterpillar Tools This is the only recommended communication device for CAT, and the only datalink device that will allow you to properly communicate with a CAT engine on dual datalinks. This function is needed for some CAT ET (Electronic Technician) functions. The PC-based service tools from Caterpillar provide the capability to access Electronic Control Modules (ECMs) from a personal computer. Many job-critical tasks can be performed with an electronic service tool.

The user can display the status of a group of parameters (temperatures, pressures, etc.) simultaneously, view active and clear logged diagnostics, display the current configuration of an ECM and much more. The service tool works with a communication adapter to allow connection to an ECM. The version and identification of the ECM is automatically retrieved and is displayed on a summary screen when the program is started. Diagnostic tests and calibrations can also be performed.

Features

Display, graph and log status parameters.

Retrieve prognostic data including histograms, engine totals for fuel used and miles traveled.

View active diagnostics and clear logged diagnostics. View events where irregularities have occurred and have been logged by the ECM.

Perform calibrations to enhance performance of the ECM.

Customize the ECM with application-specific settings.

Over 100 custom Diagnostic, Information and Service features including:

– 2D and 3D Histogram plotting capability (engine software

support required).

– Custom Status screen groups

– Snapshots (Download and display snapshot data recorded by the

ECM)

– Configuration Aid that allows upload/download of same

configuration to multiple control modules

Customised Service Tool Options

Customized service tool name

Customized graphics for the splash screen and icons

Customized installation

Aftermarket differentiation, i.e., the tool for one customer does not work on the product of another customer.

Licensing options for customer management

Flash programming of the ECM(s)

Training demonstration allows familiarity with the tool’s primary functions without connecting to ECM(s)

Perform customized diagnostic tests to identify harness problems, cylinder or component failures (Automatic Cylinder Cutout with cylinder to cylinder fueling comparison)

For Cat Electronic Technician to work with the Communication Adapter 3, the settings must be changed to select the Communication Adapter 3 as the Communication Interface Device:

Step 1 Start Cat Electronic Technician.

Step 2 Click the Stop Connect button when it appears.

Step 3 Select the Utilities menu.

Step 4 Choose “Preferences > Modify…”.

Step 5 Select the Communications tab.

Step 6 Select Cat Comm Adapter 3 (RP1210) and click OK.

NOTE: Because a growing number of products require multiple data link service, the “Enable Dual Datalink Service” checkbox has been pre-selected.

Servicing ECMs on more than one data link requires this check box to be enabled.

Failure to do this will result in undetected ECMs and reduced functionality.

More similar products can be found on www.cnautotool.com and any problem please feel free contact us.